Mobdus, a practical and reliable solution for industrial cabled monitoring

Modbus, which appeared in the 1970s, is an unavoidable communication protocol for wired M2M for industry, construction and energy. Its simple architecture, easy integration and high reliability are ideal to efficiently control or take remote readings from automated equipment.

Simple but efficient technical architecture

Based on master-slave architecture, Modbus offers high operational flexibility Its serial RTU mode speeds up data exchanges with its 8 bit encoding while allowing the connection (with repeaters) of 247 peripherals over a distance of 1200 metres. Its TCP/IP version offers speeds of 10 to 100 Mbits/second (and almost unlimited connectivity) on classic network topology such as ring or star.

Very easy integration with installations

The technical deployment of the Modbus ecosystem stands out by its simplicity. In an RTU configuration, only one serial port or cabled bus connection compatible with the RS-422 or RS-485 standards is required between the installation and the controller. For TCP/IP, the recommended connectors are RJ 45 or IP 65. The control or collection gateway often has radio transmission (GPRS, etc.) to the establishment’s information system.

A protocol renowned for its high reliability

In its modes widely used in industry, Modbus has a native frame error checking code. Known as “Cycle Redundancy Check”, it covers the entire message (recipient, function, address and number of words to read) thereby providing exchange reliability close to 100 %.

Specialised in M2M for the energy sector, France’s Webdyn has been offering a wide range of solutions to allow industrial and network equipment to communicate for over 20 years. Its very easy to deploy Modbus data gateway guarantees reliable and effective supervision of slave installations that dialogue in RTU (wired bus) or TCP (Ethernet) mode.

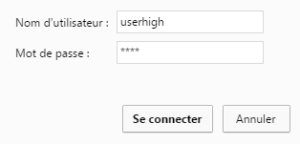

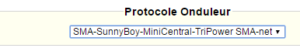

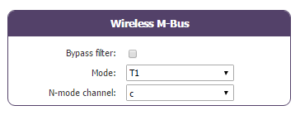

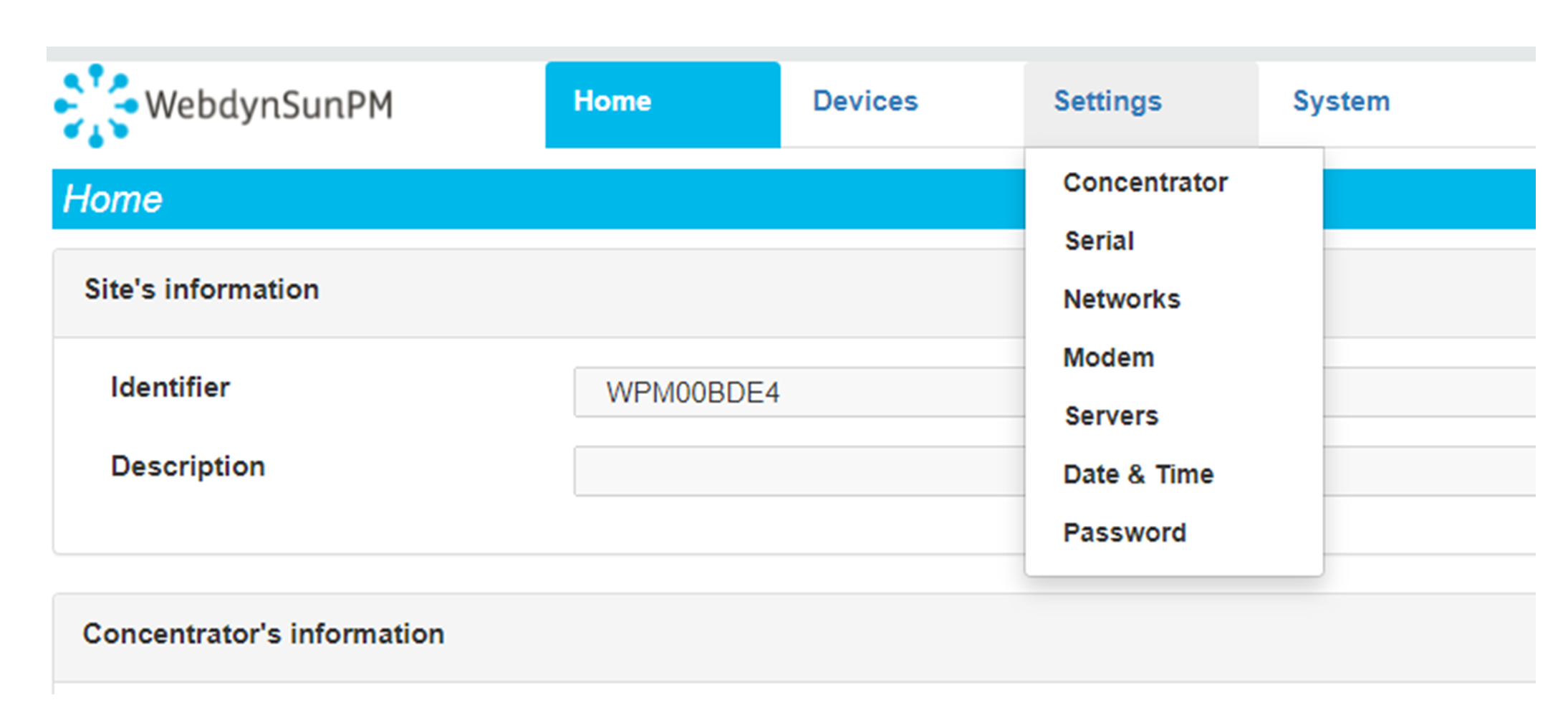

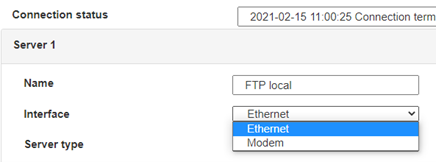

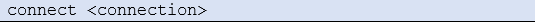

Enter the “ethernet” or “modem” connection type:

Enter the “ethernet” or “modem” connection type:

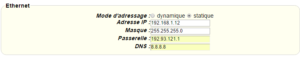

For an ethernet configuration, make sure the IP parameters are compatible with server access according to the concentrator local network configuration. For an ethernet connection, the configuration must be compatible with the concentrator’s local network topology so that it can access the servers. This configuration is done from the “Networks” configuration page (see section 3.2.2.3: “Networks”).

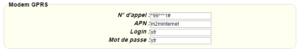

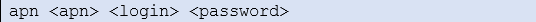

For a modem connection, the modem configuration must be correct before a connection can be set up. This configuration is done from the “Modem” configuration page (see section 3.2.2.4: “Modem”).

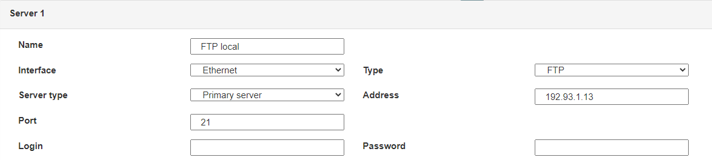

The parameters for the servers to be configured are at least the following:

For an ethernet configuration, make sure the IP parameters are compatible with server access according to the concentrator local network configuration. For an ethernet connection, the configuration must be compatible with the concentrator’s local network topology so that it can access the servers. This configuration is done from the “Networks” configuration page (see section 3.2.2.3: “Networks”).

For a modem connection, the modem configuration must be correct before a connection can be set up. This configuration is done from the “Modem” configuration page (see section 3.2.2.4: “Modem”).

The parameters for the servers to be configured are at least the following:

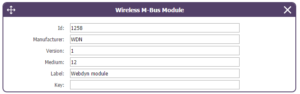

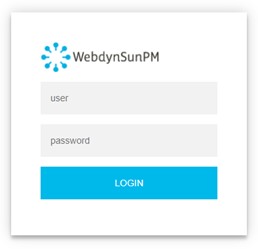

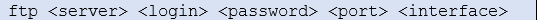

Therefore the following fields need to be configured: “Interface”, “Type”, “Server type”, “Address”, “Port”, “Login” and “Password”.

The other fields can be left at the default values subject to the directories having been properly created beforehand. See section 3.1.2: “Configuration files” for more details.

Therefore the following fields need to be configured: “Interface”, “Type”, “Server type”, “Address”, “Port”, “Login” and “Password”.

The other fields can be left at the default values subject to the directories having been properly created beforehand. See section 3.1.2: “Configuration files” for more details.

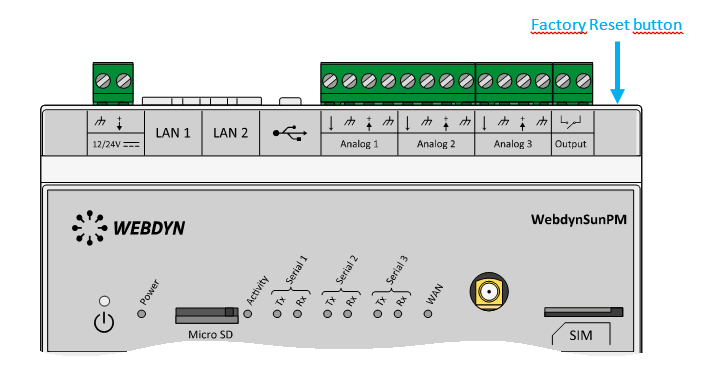

Wait. The concentrator will reboot using its factory configuration.

Wait. The concentrator will reboot using its factory configuration.